What to Do When Tank Trucks Can’t Get a Load at the Petroleum Loading Rack

Confused about problems you have at the loading rack? Is it a terminal- or truck-based issue? We’ve compiled information about some issues that can arise when you can’t get a load at the petroleum loading rack. Read through these procedures—we’re providing a quick troubleshooting guide for common problems. These scenarios will guide terminal personnel and drivers to quickly determine the cause of the problem and enable them to correct them quickly.

Terminals today are more likely to have ground proving equipment than ever before. As regulatory compliance gets more stringent, you may start to notice ground faults at the rack. A ground fault may occur for one or more reasons, from a problem at the rack or the trailer. These issues can range from a loose socket on the trailer to a bad cable on the load rack. Below are some graphics, describing what you should look for while trouble shooting.

1. Broken Wire in the Plug and Cable

Cause: When the strain relief becomes loose on the plug or junction box, the pressure grommet can no longer hold the cable tightly. This results in the cable being allowed to freely spin inside the plug or junction box. Over time, the wires twist to a point in which one or more of the wires break, resulting in, but not limited to, a ground fault.

Solution: During routine testing and maintenance, check the strain reliefs for a tight fit, and make sure the cable has not pulled through the fitting at the junction box. Also, when replacing a cable, it is highly recommended that you replace the strain relief assembly (PN 20846).

2. Corrosion in the Junction Box

Cause: When water is allowed into the junction box, it creates corrosion over time. When this happens, wire contacts may become grounded to one another. If that grounded connection takes place on the #9 wire, it may result in a ground fault. It is paramount that all efforts be made to prevent water intrusion at the junction box.

Solution: Ensure that the conduit leading to the junction box is sealed, and that all connections (i.e., pipe glands, GWATs, GWALs, seal offs, etc.) are installed per manufacturers installation guidelines. If you experience corrosion problems, find and repair the source, and clean and dry the inside of the junction box to eliminate the cross contact of the wire connections.

3. Bad Vehicle ID Module (T.I.M.)

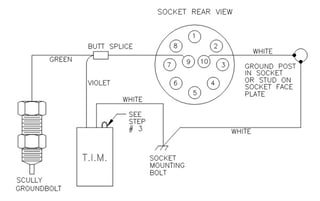

Cause: In very rare occasions, you may experience a Scully T.I.M ™ Truck ID Module or competitive vehicle ID module that goes bad. Depending on the failure, it may result in the violet and white wires becoming shorted together. This occurrence may cause a ground fault at the rack. For assistance with finding an authorized Scully dealer for replacement parts, contact us here, call 1-800-2SCULLY, or email sales@scully.com.

Solution: If the T.I.M. is not needed at any of the terminals you frequent, you can temporarily remove the T.I.M. from pin 9 on the socket. (Note: replace it as soon as you return to the repair shop or carrier dispatch.) If it is needed, replace the T.I.M. module, and notify all necessary persons of the new serial number.

4. Bad or Corroded Ground Bolt

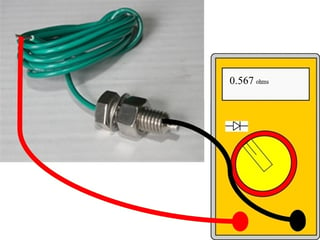

Cause: To understand a problem with the ground bolt, we must first understand how it operates. The ground bolt is a bolt that contains a diode inside of it, and is fixed into a hole drilled into the frame of the trailer. One end of the diode is crimped into the tip of the bolt, and the other to a wire that attaches to pin 9 of the socket. This connection is necessary for measuring the amount of resistance between the trailer and ground. On occasion, this bolt may be come damaged (damaging the diode), or incur corrosion between the bolt and frame (hindering the bolt to frame bond). Any of these situations may result in a ground fault.

Solution: First, disconnect the bolt from the frame and socket. As with all diodes current only travels one way, so you can test the diode for an ohms reading one way, and open circuit, the other. The ohms reading for a good bolt should be around .567 ohms. If your reading comes in below .4 ohms or above .7 ohms, the bolt is faulty. If you can read current in both directions, or have an open circuit in both directions, the bolt is faulty. If you have a good bolt—reading good ohms in one direction only—you can move to checking for corrosion. At the site, where the bolt is attached to the frame, check for corrosion or rust. If present, remove the corrosion or rust, and ensure the area is clean of any oils or debris before re-installing the bolt.

5. Compromised J-Slots on Socket

Cause: Over time the sockets will experience wear. When this isn’t handled properly, it will experience wear much faster. When attaching the cable at the load rack, the plug should be lined up with the slots, pushed to the back of the socket, and turned clockwise into position. More importantly, when removing the cable, the plug should first be pushed to the back of the socket, then turned counter-clockwise to disconnect. When these instructions are not followed, the pins on the plug will grind at the socket. Over time, this will create a loose connection between the plug and socket. If that loose connection occurs at the #9 or #10 pin, you may experience a ground fault.

Solution: If the socket is already worn, it must be replaced. To prevent future damage to the sockets, a strong emphasis on training must be in place. Train your drivers how to properly connect and disconnect the plug, and explain the problems that can occur if connecting and disconnecting is done improperly.

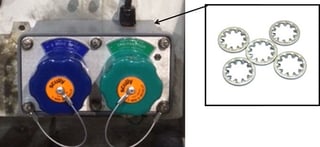

6. Poor Bond between Socket and Trailer Frame

Cause: The socket must be properly bonded to the trailer frame to get a proper ground. Resistance from pin #10 to the frame of the trailer and/or the body of the groundbolt should be ~0 Ohms. This bond can be interrupted by: loose mounting bolts, corrosion, rust, or any other material, such as paint or oils. This interruption can occur at any contact point that is between the socket and frame.

Solution: Clean all connection points between socket and frame, ensuring the holes for the mounting bolts are also clear of obstruction. You may also want to consider placing star washers on the mounting bolts. When you tighten the bolts, these washers will ensure you have a good bond

We hope this quick troubleshooting guide has shed some light on common issues surround load problems at the rack. If you have any other concerns or need assistance with finding an authorized Scully dealer for replacement parts, contact us here, call 1-800-2SCULLY, or email sales@scully.com.