Scully Product Testing: Designing Fail-Safe Overflow Prevention Products that Last

Long-lasting durability matters for Overfill Prevention and Grounding Systems, and you need assurance that your equipment will work in the field as well as the first day it was installed—sometimes under harsh conditions. How can you offer assurance? Fail-safe fluid detection and handling, with a dependable safety record over time, is an attainable goal, but it comes from following stringent protocols and using proven testing procedures.

HALT for New Product Design

Scully adopts the HALT (highly accelerated life testing) concept for new product design. HALT creates conditions that prematurely age the products, using variables in combinations, such as:

- Temperature extremes

- Corrosive environments

- UV exposure

- Vibration

- Shock

After implementing HALT on our Overfill Prevention and Grounding Systems, we analyze these aged units to understand the effect of all conditions throughout long periods of time and to judge whether the product holds up to our high levels of quality. This expectation of quality is what keeps our products running dependably in the field for so long.

Predicting the Effects of Harsh Environments

Modern weather testing techniques expose the product to repeated cycles of high-intensity UV radiation and moderate heat, followed by darkness and cooling in a corrosive high-humidity environment for a period of many weeks. This allows the corrosive atmosphere to condense, dry, and adhere to the surface of the product, and penetrate further as the product seals go through expansion and contraction as a result of heating and cooling. This combination of environmental factors was developed by a consortium of plastics and coatings companies after standard discrete salt-fog and light/heat exposure testing failed to predict the effects of the harsh environments such as Kuwait City.

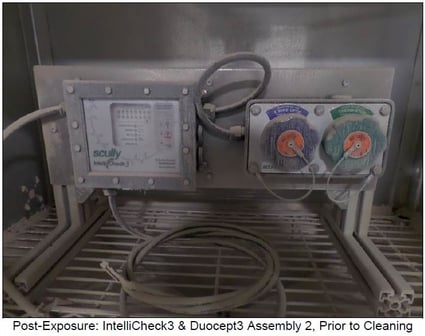

As a verification of the product integrity, the units undergoing the weathering, vibration, shock, and impact tests are subsequently tested with a pressure washer, as suggested by SAE J 1455. Some products are frozen while submerged in water, helping to guarantee they will meet the advertised Ingress Protection (IP) ratings for the life of the product. Full verification and validation (V&V), after the full battery of environmental tests are completed, gives the final assurance that our customers can select Scully products with confidence.

Committed to Safety and the Environment

At Scully, all our products are subjected to the above standards, but varying and additional standards are applicable depending on the specific product. For example, our truck-mounted products are subjected to gravel bombardment per SAE specifications; whereas, our loading rack mounted equipment is tested to railside vibration specifications per the AREMA standards.

As the pioneer in the fail-safe overflow prevention industry, Scully built its reputation on preventing spills. Eliminating the risk that hazardous petrochemicals pose to the environment, the people who handle them, and everyone involved is our top priority. The best way to fulfill this commitment is to produce exceptional products—all components of our Overfill Prevention and Grounding Systems—that are capable of checking their own operation and shutting down loading operations automatically in the case of an unsafe condition—reliably and consistently.

| An example of some of the pressure washing testing that Scully products undergo |

To learn more about Scully, our products, and testing procedures, contact us at 800-272-8559 or email us at Sales@scully.com.